Ex.No: Date:

STUDY OF BABCOCK-WILCOX BOILER

Aim: To study

Babcock-Wilcox boiler.

Theory: Evaporating the water at appropriate temperatures and pressures in

boilers does the generation of steam. A boiler

is defined as a set of units, combined together consisting of an apparatus for

producing and recovering heat by igniting certain fuel, together with

arrangement for transferring heat so as to make it available to water, which

could be heated and vaporized to steam form. One of the important types of

boilers is Babcock-Wilcox boiler.

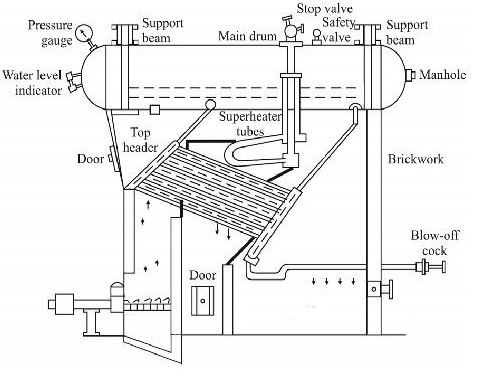

Observation: In thermal powerhouses, Babcock and Wilcox boilers do generation of

steam in large quantities.

The boiler consists essentially of three parts.

1.

A number of inclined water tubes: They

extend all over the furnace. Water circulates through them and is

heated.

2.

A horizontal stream and water drum: Here

steam separate from the water which is kept

circulating through the tubes and drum.

3.

Combustion chambers: The whole of space where water

tubes are laid is divided into three separate chambers,

connected to each other so that hot gases pass from one to the other and give

out heat in each chamber gradually. Thus the first chamber is the hottest and

the last one is at the lowest temperature. All of these constituents have been

shown as in fig.

The Water tubes 76.2 to 109 mm in

diameter are connected with each other and with the drum by vertical passages

at each end called headers. Tubes are inclined in such a way that they slope

down towards the back. The rear header is called the down-take header and the

front header is called the uptake header has been represented in the fig as DC

and VH respectively.

Whole of the assembly of tubes is

hung along with the drum in a room made of masonry work, lined with fire

bricks. This room is divided into three compartments A, B, and C as shown in

fig, so that first of all, the hot gases rise in A and go down in B, again

rises up in C, and then the led to the chimney through the smoke chamber C. A

mud collector M is attached to the rear and lowest point of the boiler into

which the sediment i.e. suspended impurities of water are collected due to

gravity, during its passage through the down take header. Below the front

uptake header is situated the grate of the furnace, either automatically or

manually fired depending upon the size of the boiler. The direction of hot

gases is maintained upwards by the baffles L.

In the steam and water drum the

steam is separated from the water and the remaining water travels to the back

end of the drum and descends through the down take header where it is subjected

to the action of fire of which the temperature goes on increasing towards the

uptake header. Then it enters the drum where the separation occurs and similar

process continuous further.

For the

purpose of super heating the stream addition sets of tubes of U-shape fixed

horizontally, are fitted in the chamber between the water tubes and the drum.

The steam passes from the steam face of the drum downwards into the super

heater entering at its upper part, and spreads towards the bottom .Finally the

steam enters the water box W, at the bottom in a super heated condition from

where it is taken out through the outlet pipes.

The boiler is fitted with the

usual mountings like main stop valve M, safety valve S, and feed valve F, and

pressure gauge P. Main stop valve is used to regulate flow of steam from the

boiler, to steam pipe or from one steam one steam pipe to other.

The function of safety valve is

used to safe guard the boiler from the hazard of pressures higher than the

design value. They automatically discharge steam from the boiler if inside

pressure exceeds design-specified limit. Feed check valve is used to control

the supply of water to the boiler and to prevent the escaping of water from

boiler due to high pressure inside.

Pressure gauge is an instrument, which record the inside pressure of the

boiler. When steam is raised from a cold boiler, an arrangement is provided for

flooding the super heater. By this arrangement the super

heater is filled with the water up to the level. Any steam is formed while the

super heater is flooded is delivered to the drum ultimately when it is raised

to the working pressure. Now the water is drained off from the super heater

through the cock provided for this purpose, and then steam is let in for super

heating purposes.

Pre

Lab Questions:

1.

What

is the function of boiler?

2.

What

are the different types of boilers?

3.

Explain

the principle of fire tube and water tube boilers?

4.

What

is meant by evaporation?

5.

Differentiate

water tube and fire tube boilers?

Post Lab Questions:

1.

Explain the working principles of various boilers?

2. Advantages of high pressure

boilers?

3.

Explain

the term enthalpy.

4.

Explain

the principles of fluidized bed combustion and pulverized fuel combustion?

5.

What

is the function of superheater, an economizer and an air pre heater?

Conclusion:

|

PO Attainment: |

|

|

Composed By:

R.Satheesh, M.E.,

Asso.Prof.,